In the world of track and field, the shot put event demands precision, strength, and optimal conditions for athletes to perform at their best. One often overlooked but crucial factor is the friction between the athlete’s shoes and the shot put circle’s surface. Friction testing in these circles has become an essential practice to ensure fair competition and athlete safety. Without adequate friction, an athlete’s footing could slip during the explosive movements required for a successful throw, leading to subpar performances or even injuries.

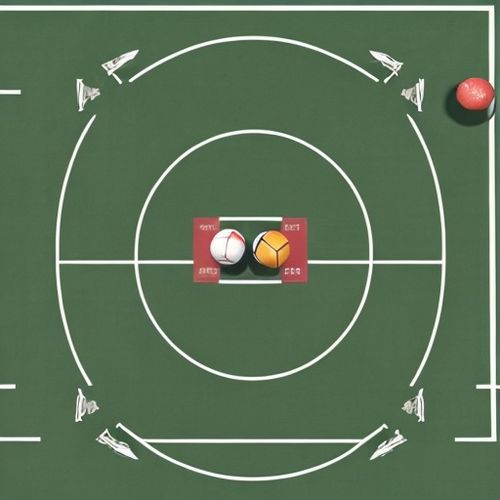

The surface of a shot put circle is typically made of concrete or a similar durable material, coated with a thin layer of paint or textured finish to provide grip. Over time, weather conditions, frequent use, and improper maintenance can degrade this surface, reducing its frictional properties. To combat this, sports engineers and facility managers conduct regular friction tests using specialized equipment. These tests measure the coefficient of friction (COF), which quantifies how much grip the surface provides. A higher COF indicates better traction, while a lower value signals potential hazards.

How Friction Testing Works

Friction testing involves dragging a weighted sled or a tribometer across the shot put circle’s surface. The device measures the resistance encountered, providing a numerical value for the COF. The International Association of Athletics Federations (IAAF) and other governing bodies have established guidelines for acceptable friction levels in competition circles. If a surface fails to meet these standards, it must be resurfaced or treated to restore proper grip. This process ensures that all athletes compete on a level playing field, where performance depends on skill and training rather than inconsistent surface conditions.

Beyond competitive fairness, friction testing plays a vital role in injury prevention. A slip during the rotational or glide technique—the two primary shot put throwing styles—can lead to falls, muscle strains, or more severe injuries. By maintaining optimal friction levels, facility managers help athletes focus on their technique without worrying about unstable footing. This is especially important in outdoor venues, where rain, dust, or debris can further reduce traction.

The Science Behind Surface Treatments

To enhance friction, shot put circles are often treated with abrasive materials or coatings. Some facilities use sand mixed into the paint, while others apply specialized non-slip coatings designed for sports surfaces. These treatments must strike a balance—providing enough grip for safety without making the surface so rough that it damages athletes’ shoes or slows their movements excessively. Regular testing ensures that these treatments remain effective over time, as wear and tear can diminish their benefits.

In recent years, advancements in materials science have led to the development of more durable and consistent surface treatments. For example, some modern shot put circles incorporate micro-textured finishes that maintain high friction even in wet conditions. These innovations are particularly valuable for competitions held in regions with unpredictable weather, where rain could otherwise disrupt events. Friction testing helps validate these new materials, ensuring they meet the rigorous demands of elite athletics.

The Human Factor in Friction Testing

While technology plays a significant role in friction testing, human expertise is equally important. Experienced technicians know how to interpret COF readings in the context of real-world conditions. For instance, a slightly lower friction reading might be acceptable in a dry climate, while a wetter environment would require higher values. Additionally, technicians assess the surface for localized wear patterns, such as areas where athletes frequently pivot, which may need targeted repairs.

Athletes themselves often provide valuable feedback about surface conditions. Many elite shot putters develop a keen sense of how different circles feel underfoot, and their observations can guide maintenance efforts. Combining quantitative friction data with athlete input creates a comprehensive approach to surface management, ensuring that both scientific standards and practical needs are met.

Future Directions in Friction Management

As sports science continues to evolve, so too will the methods for testing and maintaining shot put circles. Researchers are exploring smart surfaces that can adapt their friction properties in response to environmental changes, such as temperature or humidity. These innovations could revolutionize how athletic facilities manage traction, reducing the need for frequent manual testing and treatments.

In the meantime, regular friction testing remains a cornerstone of shot put circle maintenance. By prioritizing this often-overlooked aspect of competition venues, organizers uphold the integrity of the sport and protect the athletes who dedicate themselves to it. Whether at the Olympic level or local meets, ensuring consistent and safe surfaces allows shot putters to push their limits with confidence.

By Elizabeth Taylor/May 9, 2025

By David Anderson/May 9, 2025

By Amanda Phillips/May 9, 2025

By Victoria Gonzalez/May 9, 2025

By Rebecca Stewart/May 9, 2025

By Michael Brown/May 9, 2025

By William Miller/May 9, 2025

By James Moore/May 9, 2025

By Christopher Harris/May 9, 2025

By George Bailey/May 9, 2025

By John Smith/May 9, 2025

By John Smith/May 9, 2025

By Samuel Cooper/May 9, 2025

By Christopher Harris/May 9, 2025

By Megan Clark/May 9, 2025

By Victoria Gonzalez/May 9, 2025

By William Miller/May 9, 2025

By Natalie Campbell/May 9, 2025

By Megan Clark/May 9, 2025

By Michael Brown/May 9, 2025